In a groundbreaking move, Boston Dynamics plans to deploy its advanced Atlas robot in a Hyundai manufacturing plant later this year. This ambitious step marks a significant transition from traditional industrial automation to a new frontier where humanoid robots could effectively work alongside human employees. The evolution of Atlas from its hydraulic predecessors, which captured public imagination through viral demonstrations, is a testament to the leaps technology has made since its initial introduction in 2013. Unlike its counterparts, the dog-like Spot and the warehouse-oriented Stretch, Atlas represents a unique venture into the realm of humanoid robotics aimed at commercial application.

Functionality Beyond Human Capability

Despite Boston Dynamics remaining tight-lipped about the specific tasks Atlas will undertake, the robot is touted to perform functions that present challenges for human laborers—like lifting heavy and awkwardly shaped objects. This characteristic highlights a critical aspect of advanced robotics: while automation can enhance productivity, designing robots that mimic human dexterity opens new lanes for operational efficiency. As Boston Dynamics spokesperson Kerri Neelon states, Atlas’s potential lies in its capacity to tackle intricate tasks, allowing human workers to focus on higher-order activities that require problem-solving skills.

Humanoid Robots: Shifting Paradigms in Manufacturing

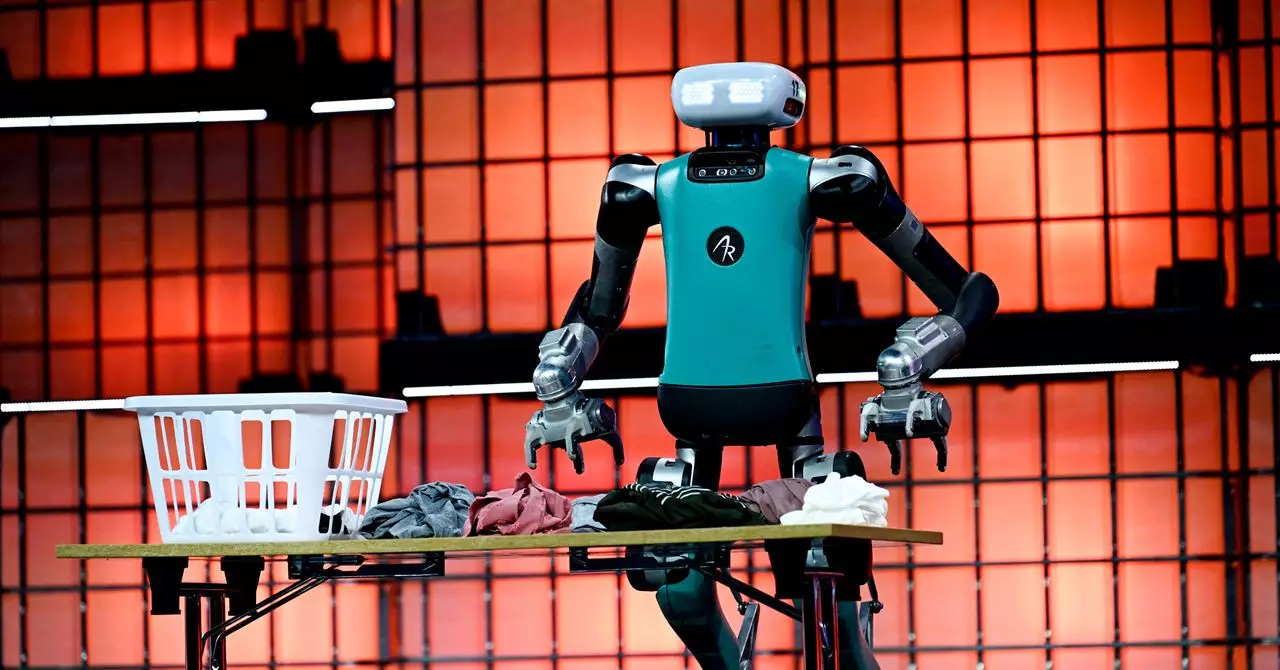

A pivotal year awaits in 2025, as multipurpose humanoid robots venture beyond research settings and into industrial landscapes, unlocking possibilities previously confined to fiction. One cannot overlook the significance of this shift: companies like Agility Robotics and Figure have already placed their humanoid robots in real-world job scenarios, illustrating a broader industry trend. The potential market for humanoid robots is vast; a report from Goldman Sachs anticipates that by 2035, the sector could soar to a staggering $38 billion. This projection underscores not only the growing interest in humanoid applications but also the necessity for businesses to adapt to a changing labor landscape.

In contrast to traditional assembly line automation, which often necessitates tailored environments to accommodate specific tasks, humanoid robots promise versatility. The ability to switch fluidly between various tasks disrupts the static nature of manufacturing processes. Jonathan Hurst from Agility Robotics emphasizes that while built automation solutions can be optimized for specific roles, the true strength of humanoid robots lies in their flexibility, positioning them as valuable assets in environments where operations vary frequently.

Challenges Along the Road to Market

Despite the excitement surrounding humanoid robotics, hurdles remain before these machines can gain widespread acceptance. A notable example is Tesla’s highly publicized Optimus robot, which has faced criticism for its reliance on human control during demonstrations—raising doubts about the viability of its autonomous capabilities. The public’s interest in the performance and functionalities of robotics has led to heightened scrutiny; evident by concerns over how quickly these technologies can be integrated into the workforce. Elon Musk has suggested that the production of thousands of these robots is on the horizon, yet complications such as supply chain bottlenecks—especially concerning scarce rare-earth metals—could delay their rollout.

The Human-Centric Approach

The design philosophy behind Atlas highlights an essential truth: our world is inherently designed for human beings, which necessitates the creation of robots that can seamlessly integrate within that framework. Boston Dynamics has acknowledged this reality in the construction of Atlas, aiming to create a robot suited for environments where human workers thrive. This approach not only fosters collaboration between humans and machines but also signifies a shift towards a more innovative and adaptable production paradigm.

As we stand on the brink of what could be a transformative shift in labor dynamics, it’s crucial to recognize the duality of opportunity and challenge that humanoid robots present. While the advantages are clear—enhanced productivity, improved flexibility, and an expanded job market for creative problem solvers—the path to this new reality is fraught with questions about autonomization, ethical implications, and the future role of human workers in an ever-evolving labor landscape. The journey of humanoid robots like Boston Dynamics’ Atlas is only beginning, and the outcomes will undoubtedly shape the future of work in profound ways.